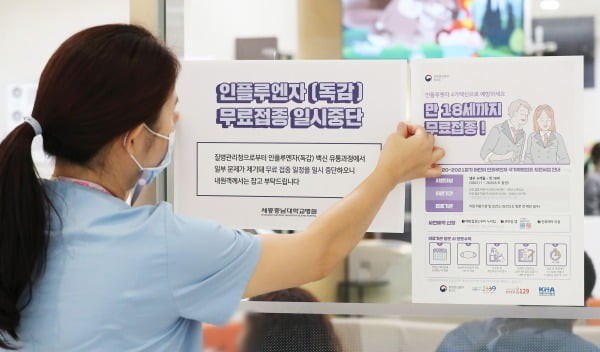

At the end of September, in the middle of the flu shot season, a problem was discovered with the distribution process of the vaccine and several shipments had to be returned. The shipments in question were left at room temperature for a brief period during transport or were shipped in trucks with faulty temperature controls. The recall affected a total of 5.78 million doses. On October 6, 2020, officials from the agency confirmed that there were 196 instances of violations in the refrigeration process of the vaccines. However, they insisted that most of them did not result in safety problems for the perishable shipment. The Korea Disease Control and Prevention Agency (KDCA) investigated. They found that of the 2,303 people injected with the unrefrigerated flu shots, 12 of them showed signs of adverse reactions, including fever, sore muscles, and a cough.

|

| ▲ Ceasing free inoculation because of spoiled vaccine. (Photo from Hankook Kyungjae) |

The World Health Organization (WHO) believes that the transportation of vaccines will inevitably include brief moments when the precious cargo will be exposed to less than ideal temperatures. However, this should be avoided to ensure the safety of the perishable materials. In the case of the flu vaccine, the average storage temperature should not be over 14.4 degrees Celsius when being transported in an 11-ton truck and 11.8 degrees Celsius when transported in a 1-ton truck for 88 minutes. In addition, the temperature must not to fall under 1.1 degrees Celsius in an 11-ton truck and 0.8 degrees Celsius in a 1-ton truck for the same given time. To ensure these shipping specifications are met, these types of volatile shipments rely on the technology used in cold chain logistics. The recalled shipments in Korea came from delivery trucks whose thermometers dropped below zero degrees Celsius in transit. In addition, some of the 11-ton trucks that travelled to the Honam, Youngnam and Jeju region stored the vaccines on the ground of an outdoor parking lot while loading them on to the 1-ton trucks. Both cases are examples of clear breakdowns in their cold chain logistics.

Vaccines are made up of perishable proteins and changes in temperature can be fatal for their functionality. Proteins can be denaturalized by many environmental factors including lighting, heat, and pressure. This is because they fall under the principles of Phase Change Material (PCM). PCM is a process in which certain substances will differ depending on the temperature and pressure they are exposed to. It is a thermodynamic process where for instance a gas changes to a liquid or solid. Varying the storage temperature of flu vaccines in transport will affect the reliability and safety of the perishable material.

|

| ▲ ElephantBio23 Cold Chain Package. (Photo from Joong-ang Ilbo) |

Amid growing concerns about the safety of vaccines in transport, Korean companies have begun developing new cold chain technologies. The Elephant Bio 23 is an example of innovative cold chain packaging that meets international standards. The bio-transport container can maintain a temperature of 2 to 8 degrees for more than 120 hours without relying on external power sources. The Elephant Bio 23 already passed the international standard temperature verification system and reproducibility evaluation. It also passed the report preparation and transportation verification process. The new Elephant Bio 23 is lighter, longer lasting, and eco-friendly.

When a truck is turned off, the air conditioning and refrigeration functions stop. When the drivers have other business to attend to, or when drivers are loading and unloading cargo, they turn off their engines to avoid wasting money. Therefore, new technology that addresses the shortcomings in cold chain logistics using old trucks is necessary. There are new technologies being developed in cold chain vehicles and packaging in anticipation of the need to distribute a Covid-19 vaccine safely worldwide. In the meantime, these innovative new products can be tested and put to use when distributing other perishable items such as our much-needed flu vaccines. The safety of our society depends on it.

정소연, 김건희, 박지안 dankookherald@gmail.com

![[Campus Magnifier] Let's Surf the Library!](/news/photo/202404/12496_1765_4143.jpg) [Campus Magnifier] Let's Surf the Library!

[Campus Magnifier] Let's Surf the Library!

![[Campus Magnifier] Let's Surf the Library!](/news/thumbnail/202404/12496_1765_4143_v150.jpg)